The factors that affect spinning production capacity include equipment, technology, operations, raw materials, environment, etc. Equipment is the foundation, technology is the guide, operation is the guarantee, raw materials must be reliable, and the environment must be stable.

01 Equipment

Equipment is the foundation, and good equipment is the guarantee of product quality. The equipment work mainly focuses on striving to improve the status of the equipment, and adopts measures such as zoning, grading, and model machines to reduce breakages per thousand spindles. When controlling thousands of spindles, the number of broken ends should be within 8 strands of cotton and within 5 strands of rayon. Adjust the distance of the wire ring cleaner appropriately according to the type. The cleaner should not be loose or have burrs. Choose high-quality rubber rollers and aprons. Currently, using high elasticity and low hardness rubber rollers is an important way to improve yarn quality and reduce end breakage. Regularly wash and grind the rubber rollers to check for eccentric bending, and divide them into grades, zones, and sections. When using it, the apron rings should be cleaned and replaced regularly, and be careful not to use new ones on the upper and lower apron rings at the same time. The cot roller grinding cycle is formulated for special varieties. For Rokas mechanical compact spinning, it is easy to cause the front cot roller to be dented, resulting in difficult work, large-area end breakage, and a significant increase in the number of cuts per 10,000 meters of winding. By constantly adjusting the cycle, our company spins 14.58 tex in a compact, back-grinding process once a month, and the rubber rollers are turned around once every half month.

The machine’s head-breaking time when it spins thousands of spindles determines the number of machine blocks. If the machine’s head-breaking time of thousand spindles is reduced by 50% on the original basis, the number of machines’ machine blocks can be increased by 25 %. In the situation of labor shortage in the textile industry, it can not only solve the labor shortage situation, but also save enterprise costs.

02 Process

Speed

Speed is the main factor affecting the output of spinning yarn. Factors, increase the speed on the premise of ensuring stable life in the workshop, reaching the standard number of broken ends per thousand spindles, not affecting product quality, and meeting customer requirements. The fluctuation speed of the raw material should also change accordingly. When the raw material has good maturity, low lint content and long main body length, the speed can be increased. When the traveler used is lighter, the speed can be increased appropriately. The speed also varies depending on the variety. Generally, the speed of siro spinning is about 10% lower than that of single yarn. In addition, the spindle speed is directly proportional to the hairiness. When the spindle speed exceeds the critical value, the hairiness of the yarn increases significantly.

Twist

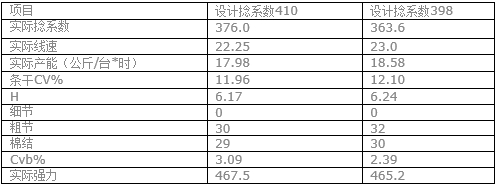

The twist of spun yarn is also a key factor affecting the yield, such as C 29.2 tex variety The design twist coefficient was reduced from 410 to 398, and the production capacity per unit increased by 3.2%. The production quality data is shown in Table 1.

Table 1 Product quality data when the design twist is different

From It can be seen from the table that appropriately reducing the twist coefficient can increase output. Of course, if the twist coefficient is too small, the strength will be reduced and the hairiness will be increased. The choice of spinning twist coefficient mainly depends on the final customer’s requirements for the type and quality of spinning yarn. Excessive twist coefficient will make the yarn surface feel hard and reduce the spinning productivity. The twist coefficient of roving also has a certain relationship with the quality of spinning yarn and the breakage of spinning yarn. Appropriately increasing the twist coefficient of the roving is beneficial to the control of fibers in the drafting area of the spinning yarn, improving the yarn evenness, and preventing the formation of details due to accidental drafting during the unwinding process of the roving. However, an excessively high twist coefficient will often result in poor drafting of the spun yarn, an increase in thick details, or even failure to draft, causing a large number of ends to break, thereby affecting the output of the spun yarn. Therefore, the roving twist coefficient must also be selected reasonably.

Selection and equipment of ring travelers

Use time and life cycle of ring travelers, traveler models and The matching conditions with the steel ring will affect the yarn breakage. When the ring shrinks and the balloon ring expands, it is easy to hit the gauze plate, causing increased hairiness. The type of traveler must match the steel ring. When the ring type does not match, it is easy to cause flying travelers and increase breakage. Only by selecting appropriate steel ring travelers for different yarns can hairiness be effectively reduced and ends broken. The weight of the traveler also has a certain impact on the yarn breakage. When it is too heavy, the wire ring is heavy and the tension is high, and the yarn will break more often; when it is too light, the wire ring is light and the balloon ring is large, making it easy to break the yarn board. , the yarn has many broken ends. The general principle of arranging the weight of the traveler is: try not to touch or lightly touch the yarn separation plate with small yarns, and do not rub the bobbin head with large yarns.

The diameter of the steel ring affects the spinning speed. The following is the comparative data of the C 36.4 tex variety using steel rings with diameters of 48 mm and 54 mm. See Table 2. .

Table 2 Effect of ring diameter on yarn quality and spindle speed

After testing It was found that when spinning C 18.2 tex with a steel ring with a diameter of 38 mm, the spindle speed can be increased by 500 r/min compared with a steel ring with a diameter of 40 mm, but the weight of the full bobbin is 4 g lighter than that of a steel ring with a diameter of 40 mm. , increasing the doffing cycle. Small steel rings are more suitable for use on long spinning cars with automatic doffing devices, which not only increases output but also ensures quality.

Make good use of new equipment

Choosing appropriate equipment also has a certain impact on product quality. Using a spun yarn collector can also increase the spinning speed appropriately. The collector has achieved good application results in our company, see Table 3.

Table 3 Effect of aggregator on yarn quality and vehicle speed

The collector bundles the edge fibers, reducing the static electricity generated on the heating surface of the rubber roller during operation and adsorbing the fibers to cause glue. The roller flowers and velvet roller flowers reduce the velvet roller flowers, which in turn increases the manufacturing rate. The quality of the velvet roller flowers with a collector and without a collector is very different. After experiments, it was found that the use of a collector can not only increase the output, but also save money. Cost.

Pack size

The forming size of each package also determines the output, the ratio: large packages of roving, From 1.30 kg per roving to 1.50 kg, the capacity increases by 15.4%, and the workload of the operator in changing rovings is also reduced by 15.4%. This allows to expand the number of roving units and reduce the amount of coarse sand. In addition, large volumes of spun yarn are used The installation not only reduces the workload of the doffing operator, but also reduces the workload of the winding operator, reduces yarn waste, reduces the loss of equipment, and saves gas consumption.

03 Operation

Reducing instantaneous yarn breakage, reducing the amount of suction cotton, and reducing empty spindles are effective measures to improve production capacity. Rubber rollers, aprons, and rollers, If the winding is not processed in time, the roving section is not replaced in time, the empty roving is not timely, the flute tube is blocked, the yarn waste on the spindle is not processed in time, improper operation, floating ends, flying flowers, etc. can all lead to an increase in yarn breakage. The stopper should strengthen patrols and In the work of preventing and catching defects, timely clean up the accumulation of cotton in the suction box, do a good job in cleaning and sanitation, and prevent the occurrence of rubber rollers, rubber rings, and rollers. When dealing with broken ends, be quick first and then slow to prevent large-area broken ends. , and include instantaneous decapitation as an assessment item. At the same time, the work operation method is optimized, the operator is responsible for special joints, and the cleaner is responsible for cleaning, simplifying the operation.

04 Raw Materials

o:p>

When the raw materials fluctuate greatly, the cotton composition is unstable and sometimes good or bad. When the maturity of the raw materials is poor and the short staple rate is high, it is easy to cause large areas of spun yarn. Broken ends. The components of each cotton category are determined based on the specific technical indicators of raw cotton, but the technical indicators of each batch of raw cotton should not be too different. The main component generally accounts for about 70% of the total cotton, and the number of pairs of cotton is generally 5~ Team 9, in order to reduce the fluctuation of yarn quality, the maximum mixing percentage is generally about 25%. The number of raw cotton batches received on the same day generally does not exceed two batches. In percentage terms, it should not exceed 15%.

05 Environment

Temperature and humidity affect spun yarn breakage, thereby affecting spun yarn output. When the temperature is relatively low, the rubber roller becomes hard, which easily causes the spun yarn to pull. When the relative humidity is low, flying flowers in the spinning environment attach to the spinning balloon, causing end breakage in the spun yarn, resulting in unstable workshop life. Generally, the temperature of spun yarn is controlled at 23 ℃ ~ 25 ℃, the relative humidity is controlled at 59% ~ 62%, so that the moisture regain rate of the spinning yarn is slightly lower than the moisture regain rate of the roving yarn, and the roving yarn is in a state of moisture release in the spinning yarn.

06 Operation efficiency

Improving operation efficiency is an effective measure to ensure output. Equipment maintenance time accounts for a large part of the equipment operation rate. A large proportion not only ensures the equipment is in good condition, but also reduces equipment maintenance time and improves operation rate.

Improve equipment accuracy and reduce maintenance cycles

Spinning and combing equipment are the productivity processes of spinning mills, and they are mastered according to the flat car Based on equipment wear and equipment status, we have formulated scientific and reasonable projects and standards for large and small flat cars, departmental maintenance, and daily maintenance to effectively ensure that the equipment is in good condition and shorten the shutdown time for unnecessary equipment maintenance. The original three-year service life of a large flat car was changed to five years, and the six-month service life of a small flat car was changed to one year, with a 4-month maintenance guarantee. At the same time, according to the new equipment, it was equipped with bearings, automatic lubrication, and increased oil viscosity to ensure frequent refueling and less refueling. The required parking time in the original cycle was 1,683.8 hours/month, but now it is 1,145.1 hours/month, a saving of 32%. To improve operating efficiency, we must not only improve labor efficiency, but also make careful plans to minimize significant spinning changes and shorten unreasonable shutdown times. At the same time, doffing workers work at a fast pace, which is directly linked to output. It is recommended to use automatic doffing machines (automatic intubation) for mid-range yarns to improve work efficiency and save labor.

Online monitoring

Adopt electromechanical integration and implement computer online monitoring. Our company has established all spinning yarns and computer centers since 1999 Through the Internet, the operating dynamics, output and process parameters of each vehicle can be seen at a glance, and the machine spinning dynamics can be grasped in real time for easy control and management.

In short, there are many factors that affect production capacity, including mechanical equipment, technology, operations, etc. Improving production capacity and obtaining greater profits is what every enterprise pursues. If you want to improve Production capacity must ensure the integrity of the equipment, the rationality of the process, the high labor efficiency, and the thoroughness of the plan. Strengthen operation management (cleaning, tours, stand arrangement, etc.) and equipment status maintenance, reduce empty spindles, broken ends for various reasons, unreasonable parking and doffing time, and improve equipment operation rate. The size of the spun yarn breakage rate has a direct impact on the product quality. The control of the spun yarn breakage involves all aspects of production, whether the operation management is sound, whether the operating technical level is excellent, and the work area to reduce the spun yarn breakage is wide and large. Work in all aspects is required to effectively reduce the yarn breakage rate, reduce the amount of air-absorbing cotton, and increase production capacity. </p